High Cpu Plc Usage – Simple Steps To Boost Performance!

I once had a frustrating issue with high CPU usage on my PLC, which caused unexpected delays in my automation processes. After hours of debugging, I realized it was due to an inefficient looping routine I had overlooked.

High CPU PLC usage can result from inefficient programming, overloaded tasks, or excessive communication requests. Optimize logic and streamline processes to reduce CPU load and improve system performance.

Stay tuned with us as we dive deeper into the topic of high CPU PLC usage, exploring its causes, solutions, and best practices to optimize system performance!

What is High CPU PLC Usage?

High CPU usage in Programmable Logic Controllers (PLCs) refers to situations where the CPU of a PLC operates at or near its maximum capacity for extended periods. This can lead to inefficiencies, slow system responses, and even potential system failures if not addressed.

PLCs are the backbone of modern industrial automation systems, handling critical tasks such as process control, data acquisition, and communication. High CPU usage indicates that the controller is overwhelmed, which can disrupt operations and compromise system reliability.

Definition and Importance of CPU Usage in PLCs

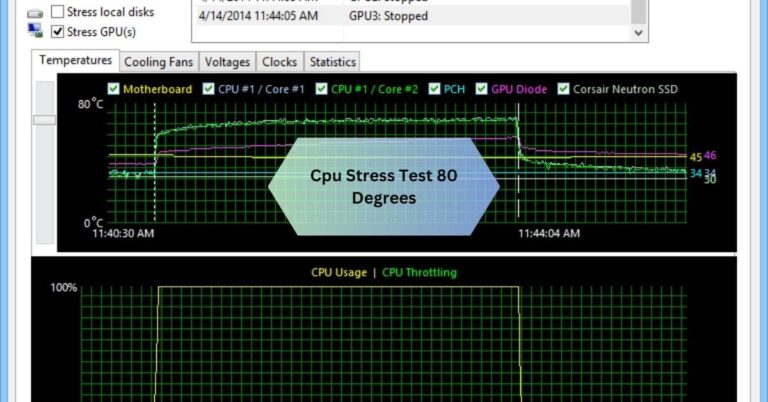

CPU usage in PLCs measures the percentage of computational resources being utilized by the controller. It reflects how efficiently the PLC handles its tasks, including running control logic, executing communication protocols, and managing inputs and outputs (I/O).

The importance of monitoring CPU usage lies in ensuring system stability and performance. Optimal CPU utilization guarantees smooth operations, reduces wear and tear on the system, and minimizes downtime. Conversely, excessive CPU usage can degrade system performance, increase maintenance costs, and negatively impact production timelines.

Signs of High CPU Usage in PLC Systems

Identifying high CPU usage early can prevent system failures. Common signs include:

- Delayed Responses: The PLC takes longer to execute commands, causing noticeable lag in system operations.

- Missed Scans: Programs fail to complete their scan cycles within the designated time, leading to operational gaps.

- Communication Issues: Slower or failed communication with other devices or systems due to resource contention.

- Error Codes or Alarms: The system generates fault codes or alarms indicating overload or delays in execution.

- System Crashes: The PLC may restart or shut down unexpectedly due to excessive load.

Also Read: How Mnay Cpu Count Arma 3 – Discover Core Usage Tips Now!

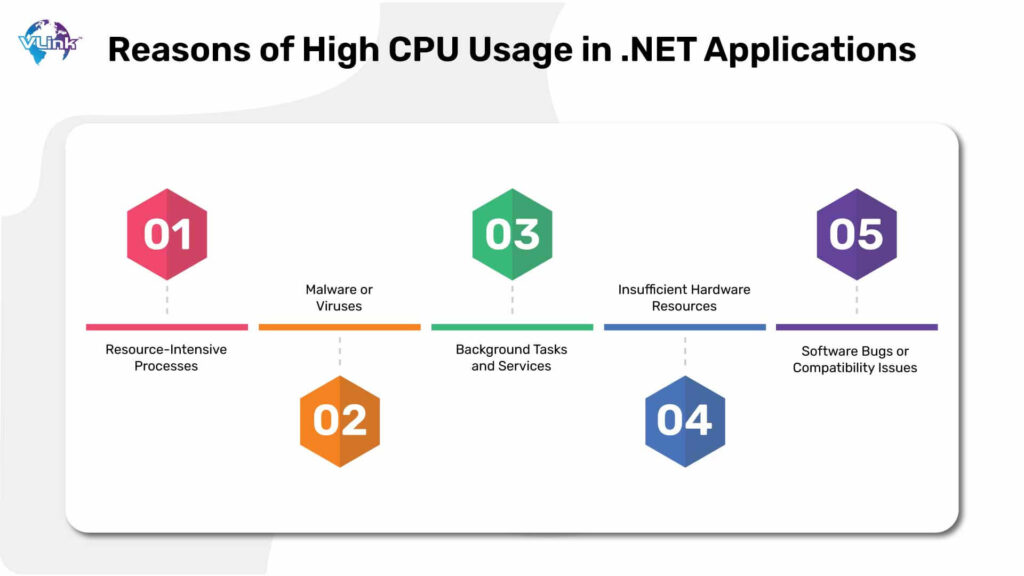

Causes of High CPU PLC Usage!

High CPU usage in PLC systems often stems from specific operational or programming issues. The most common causes include:

Inefficient Programming Logic

Poorly designed logic can overwhelm a PLC. Examples include:

- Excessive Loops: Unoptimized or infinite loops consume excessive CPU cycles.

- Complex Calculations: Performing computationally intensive tasks unnecessarily on the PLC instead of using external devices.

- Unoptimized Code: Redundant or overly complex code that increases scan time.

Overloaded Communication Tasks

Communication-heavy operations can strain the PLC, especially when multiple devices interact simultaneously. Common scenarios include:

- High-Frequency Data Polling: Continuously fetching data from sensors or other controllers at high rates.

- Inefficient Protocols: Using protocols that require more processing power than necessary.

- Unnecessary Data Traffic: Transmitting redundant or irrelevant data between devices.

What causes high CPU usage in code?

High CPU usage in code happens when the program uses too many resources to perform its tasks. Common causes include inefficient loops that run too many times, complex calculations that take too long, and unnecessary operations that add extra work.

Poorly written code with redundant or outdated instructions can also overload the CPU. Excessive data handling, like constant communication or processing large amounts of data, is another reason. Simplifying the code and optimizing tasks can help reduce CPU usage.

Solutions to Optimize High CPU PLC Usage!

Addressing high CPU usage requires a combination of streamlined programming, task management, and system design improvements. Below are effective strategies:

Streamlining Programming Logic

Efficient programming is key to reducing CPU load. Techniques include:

- Optimizing Loops: Use conditional statements to minimize unnecessary iterations.

- Modular Programming: Break down large programs into smaller, reusable modules for easier debugging and execution.

- Simplifying Calculations: Shift complex computations to external devices, such as HMIs or industrial PCs, when feasible.

- Removing Redundancies: Audit the code for unnecessary or duplicate instructions.

Managing Task Prioritization and Timing

Balancing tasks ensures the CPU focuses on high-priority operations first. Consider these strategies:

- Adjusting Scan Times: Increase the scan interval for non-critical tasks to reduce CPU load.

- Task Prioritization: Assign higher priority to critical processes and lower priority to less critical ones.

- Using Interrupts: Replace polling with event-based triggers where possible to reduce processing overhead.

- Load Distribution: Distribute tasks across multiple PLCs if the current system is overburdened.

Also Read: Cpu Voltage Reference On Overclock – Key to Overclocking Stability!

How Other Solutions Address High CPU Usage!

Understanding how competitors tackle high CPU usage offers valuable insights for improvement. Let’s analyze the approaches of two leading brands:

Brand A: Features and Performance

Brand A focuses on hardware efficiency and user-friendly software. Key strategies include:

- Optimized Firmware: Regular updates improve processing efficiency and minimize unnecessary CPU usage.

- Advanced Diagnostics: Built-in tools identify resource bottlenecks and suggest corrective actions.

- High-Performance CPUs: Premium models include multi-core processors designed for parallel task execution.

Brand A’s solutions emphasize robust hardware that complements efficient software, reducing the likelihood of CPU overload.

Brand B: Best Practices in Optimizing CPU Usage

Brand B prioritizes software-level optimization and modularity. Notable practices include:

- Template-Based Programming: Predefined templates standardize programming, reducing errors and inefficiencies.

- Integrated Load Balancing: Automated tools distribute tasks across multiple PLCs in a network, enhancing scalability.

- Customizable Communication Protocols: Tailored communication settings optimize data transfer without overloading the CPU.

Also Read: Boost Performance with Proper CPU VDD Voltages!

FAQS:

How do I fix high CPU usage?

To fix high CPU usage, optimize your code by removing unnecessary tasks, simplifying loops, and reducing complex calculations. Also, adjust task priorities and scan times to balance the workload.

What is the CPU in a PLC responsible for?

The CPU in a PLC handles processing instructions, running programs, and managing communication with connected devices. It ensures the system performs tasks like controlling machines and monitoring operations.

Why is CPU usage so high all of a sudden?

Sudden high CPU usage can happen due to a new, inefficient program or an increase in tasks like heavy data communication. It can also result from hardware issues or errors in the system’s logic.

How can I check CPU usage in a PLC?

You can check CPU usage through the PLC’s software or diagnostic tools, which display resource usage. Look for the CPU load percentage to see if it’s too high.

What happens if a PLC’s CPU is overloaded?

If a PLC’s CPU is overloaded, tasks may slow down, miss their timing, or cause the system to crash. This can disrupt operations and lead to system errors or downtime.

Conclusion

Managing high CPU usage in PLC is essential for maintaining smooth and efficient operations in automation systems. By addressing common causes like inefficient programming logic and overloaded communication tasks, you can optimize performance and prevent system disruptions. Regular monitoring, streamlined processes, and adopting best practices ensure the CPU operates within safe limits, enhancing the reliability and lifespan of your PLC. Proactively solving CPU-related challenges keeps your system running effectively, minimizing downtime and maximizing productivity.